Pre-consultation

Please provide detailed equipment usage environment and natural climate, including wind load, earthquake level, maximum and minimum temperature etc. due to the designability of FRP products. The design department of FYGRP will calculate according to the customer’s requirement and provide the best quality products and services. We will keep in touch with the customer at all times. It’s our greatest wish to solve our customer’s problems.

Product Design

Our design team has working experience for more than 20 years. We simulate the deformation and stress of the product after usage by using finite element software, and verify product design results to ensure its applicability and safety. The solution designed by our team includes the most cost-effective FRP products and provide installation drawings and calculations to our customer. The design calculations, drawings, comments and specifications prepared by FYGRP can be incorporated into the design dossier that designer submit to engineer.

Manufacture

FYGRP company manufactures according to design requirement. The inner liner of Fiberglass Reinforced Plastic (FRP) tanks , vessels and pipe is made with advanced spraying process using Venus automatic spray gun. Meanwhile spray fabrication to raw material on hydro pressure rotated cantilever mandrel and record for usage verification.

FYGRP adopts low pressure airless method to spray resin and fiberglass to ensure uniform thickness and appropriate ratios of resin and glass, thus obtain optimum corrosion resistance and mechanical integrity.

All GRP vessels and pipes are manufactured by filament winding controlled by computer in order to meet particular customer requirement. Resin and reinforced materials are carefully selected according to operating conditions of vessels and pipes.

Quality inspection service

It would cause unnecessary problems without rigorous, comprehensive inspections to ensure product quality, which is as vital as design experts. So inspectors in FYGRP company have experience of many years in composite industry.

Once detailed specification and project design completed, Inspections during fabrication, installation and operation become critical. Quality assurance starts with auditing the selected fabrication workshop, and then inspect and supervise workshop regularly.

Inspections on site include stack and its inner liner, scrubber and large tanks. FYGRP inspectors also supervise the installation of piping, tanks fabricated in factory, stack and its inner liner, scrubbers and large tanks.

To ensure optimum performance of operating systems, many factories rely on FYGRP inspection programs which includes visual inspection and non-destructive testing as well as raw material inspection。

Package

FYGRP can provide appropriate package for products in order to meet road, railway, sea and air transportation.

Package type:

- wooden saddles,

- wooden platform and air bubble film,

- crates,

- wooden cases.

Packaging Mark

FYGRP can make any mark according to customer requirement.

And meet national laws and regulations.

Transportation

GRP tanks and pipes etc. that DN4000 and below are transported by truck, container transportation for export products. Do special protection for special products during transportation. For DN4000 and above, manufacture on site. For export products, raw materials, tools and equipment are delivered to the destination to manufacture.

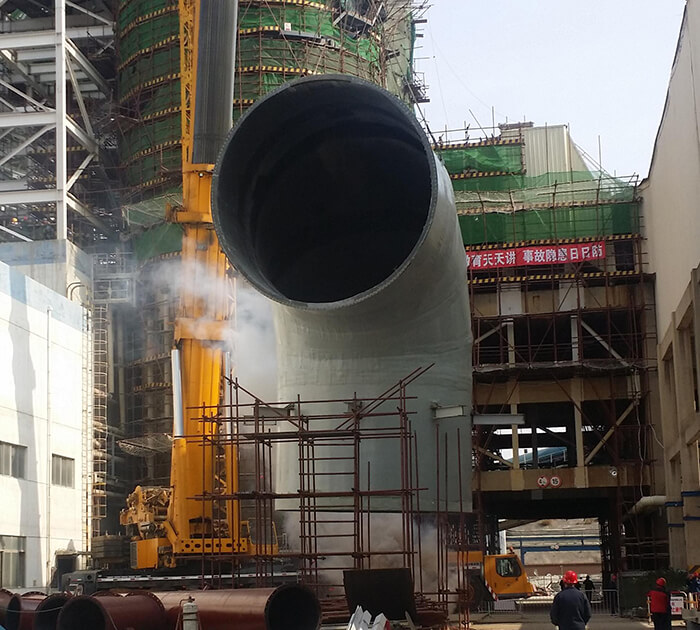

Installation on-site

FYGRP has fully equipments and is capable to install FRP products on site. All our installers are trained, and fully meet industry and safety requirements.

We have special equipment to install FRP tank and pipe. Equipments are delivered to construction site, so do tools and brackets. FYGRP provides professionals to remove, lift and install FRP tank, filter, sediment vessel, scrubber, pipe, flange etc. according to customer requirements.

Installation and assembly of tank and pipe should meet the local safety regulations in the country where the product will be used.

FYGRP provides completed service according to customer requirement, coordinate services such as crane and other necessary lifting equipment.

Quality control in-factory and on-site is our business principles all the time. Our products have been passed quality management system certification of ISO9001:2018.

Our engineer and technicist have professional knowledge and rich experience in respect of repairing damaged FRP tank, pipe and vessel etc. Each maintenance project is designed in advance and use appropriated materials such as resin in order to ensure the job is done well at the first time, let the customer reassure.

FYGRP can decrease downtime according to the customer schedule.

Repairing

Our site servicer has rich experience, in accordance with engineer requirement, and is able to quickly respond routine maintained demands of customer and various emergency situations. Service and repairing department of FYGRP can advise the customer to develop the inspection and maintenance plan which help to extend the lifetime of FRP products and equipment and reduce downtime.

FRP products maintenance and repairing service include:

Repairing/refurbishing for oil tank

FRP tank inspection

Underground tank

Pipe repairing

Modifications on-site

Field welding

Tank liner replacement

The third party consulting

Warranty

FYGRP provides customers with a warranty period of 24 months after the commissioning is qualified, or 30 months after delivery (whichever comes first). The warranty scope covers defects caused by mechanical properties and corrosion properties of the medium. Natural environmental factors are not covered by the warranty. FYGRP products are protected by product policies and provide customers with a civil compensation cap of US$1 million per order.