RPM Pipe

FYGRP Mortar Pipe

1.Structure

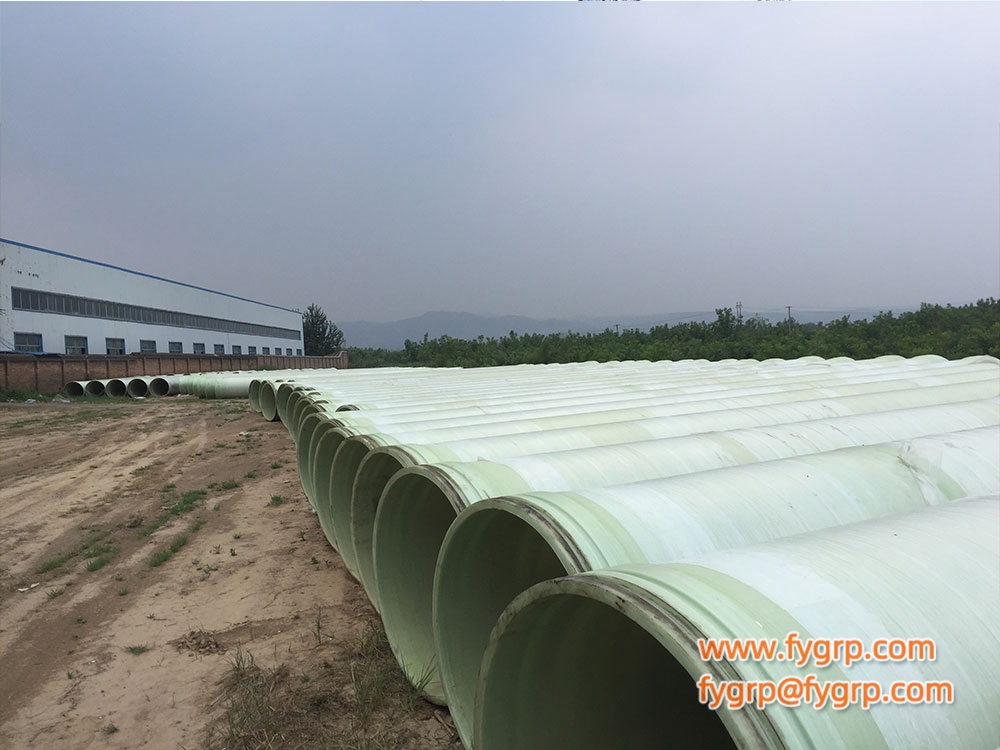

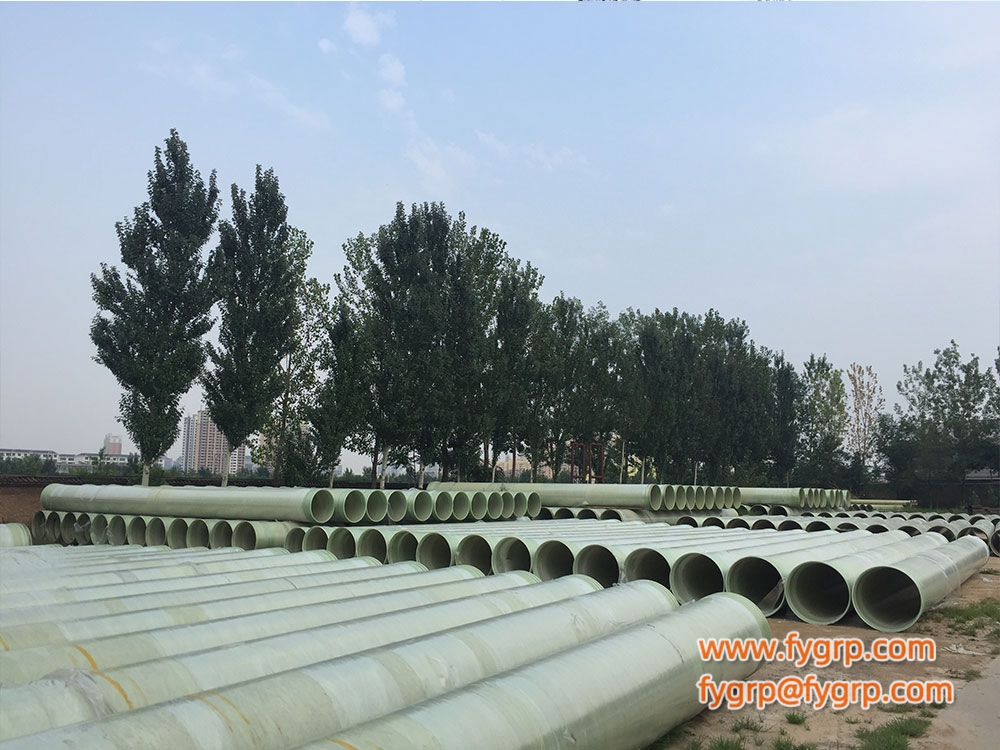

The raw material of mortar pipe is resin (select food resin for potable water), fiberglass, silica sand, and made using special process. The middle layer adopts silica sand and resin, which can improve stiffness and save cost, satisfy the requirement of transportation water and oil at large diameter under ambient temperature. Pipe diameter is 300-4000mm, the length is 12-18m/piece.

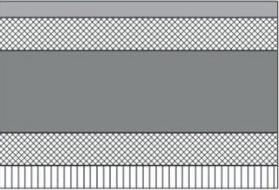

From top to bottom:

Outer protection layer (resin)

Outer structural layer (fiberglass+resin)

Mortar layer (silica sand+resin)

Inner structural layer (fiberglass+resin)

Inner liner (100% inner resin)

2. Application

(1) Drinking water transportation

(2) Sewage treatment

(3) Sea water transportation

(4) Power plant circulating pipe

(5) Chemical corrosive medium transmission

(6) Oil and gas transmission

(7) agricultural irrigation

3. Advantages

Advantages of FRP mortar pipe

1)Good corrosion resistance, no effect to water quality.

FRP pipes can resist corrosion of acid, alkali, salt, sea water, untreated sewage, corrosive soil or groundwater, and numerous chemical fluids.

2)Pollution proof and moth resistance

The surface of unsaturated polyester resin is clean and smooth, and will not be contaminated by microorganisms such as shellfish and fungi in the ocean or sewage

3)Good heat resistance and frost resistance

It still has good toughness and extremely high strength under -30℃, and can be used in the range of -50℃- -80℃ for a long time. The pipe can also work above 110℃ in the case of adopting special formula resin.

4) Light weight, high strength, convenient transportation and installation

Its specific gravity is 1.65-2.0, only 1/4 of steel, the hoop tensile strength is 180-300MPa, the axial tensile strength is 60-150MPa. Bell and spigot connection, quick and simple installation.

5) Small friction resistance, high conveying capacity

Inner wall of FRP pipe is very smooth, roughness and friction resistance is very small. The roughness coefficient is 0.0084, while the n value of concrete pipe is 0.014, and that of cast iron pipe is 0.013. Therefore, FRP pipe can significantly reduce the fluid pressure loss along the pipe and improve the conveying capacity

6) Good electrical and thermal insulation

Insulation resistance is 1012-1015Ωcm, the heat transfer coefficient of FRP is very small, only 0.23, 50 ‰ of steel.

7) Good abrasion resistance

8) Low maintenance cost

There is no need to provide measures such as anti-rust, anti-fouling, insulation, insulation and maintenance. No need to provide pole resistance protection for buried pipes, which can save maintenance cost of more than 70%.

9) Well-adapted

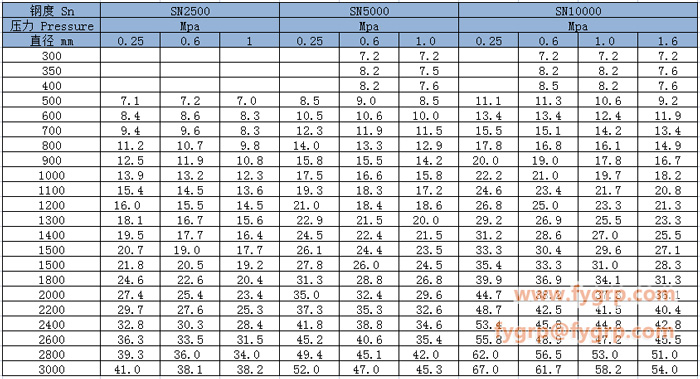

Design and manufacture pipes with different pressure and stiffness grades according to customer’s specific requirements such as different flow rate, different pressure, different buried depth and load condition;

10) The engineering life is long, safety and reliability

Base on simulation test in laboratory, the service life of FRP pipe can be more than 50 years

11) Comprehensive benefits of project is good

The comprehensive benefits of FRP piping are considerable. Specially, the larger the pipe diameter, the lower the cost. Buried pipe can be used for several generations without overhauling annually which give the superior comprehensive benefits.

4.Physical Performance

Physical properties of mortar pipe | |

Specific gravity | 1.75-1.8 |

Hoop tensile strength | 25-300N/mm2 |

Axial tensile strength | 54N/mm2 |

Hoop bending flexible modulus | 19500N/mm2 |

Heat conductivity coefficient | 0.25kcal/m2.h.c |

Coefficient of thermal expansion (axial) | 30*10-6|/℃ |

Specific heat | 0.3kcal/kg℃ |

roughness coefficient | C=145-150 |

5.Specification

Please contact tc@fygrp.com for details