Tower

FRP scrubbers are very popular in many fields such as liquid storage, water treatment, FGD system, chemical processing and pollution control, the gas cleaning process, controlling gas emissions, especially polluted gases, waste incineration and power generation processes. Because:

In comparison to metal or rubber-lined steel products, Fiberglass reinforced plastic (FRP) has many advantages.

FRP is very light-weight, very strong and can be produced in a wide range of diameters, which has a direct impact in terms of extending the service life of equipment and cost saving.

In addition, FRP is a durable material compared to traditional material, which means that FRP has significant benefits in terms of abrasion resistance, chemical corrosion, anti-rust, as well as extremely low and high temperatures. This makes it a long-lasting solution and low maintenance costs to clients.

The inside surface of FRP scrubbers is smooth, having excellent flow characteristics and easily cleaning.

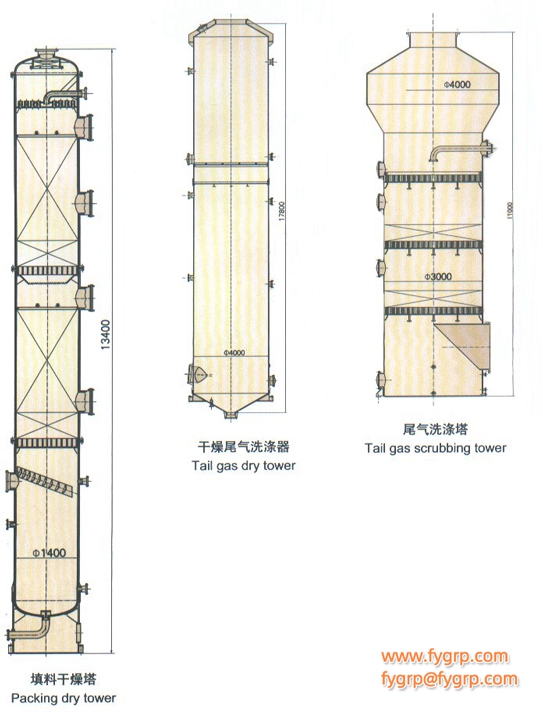

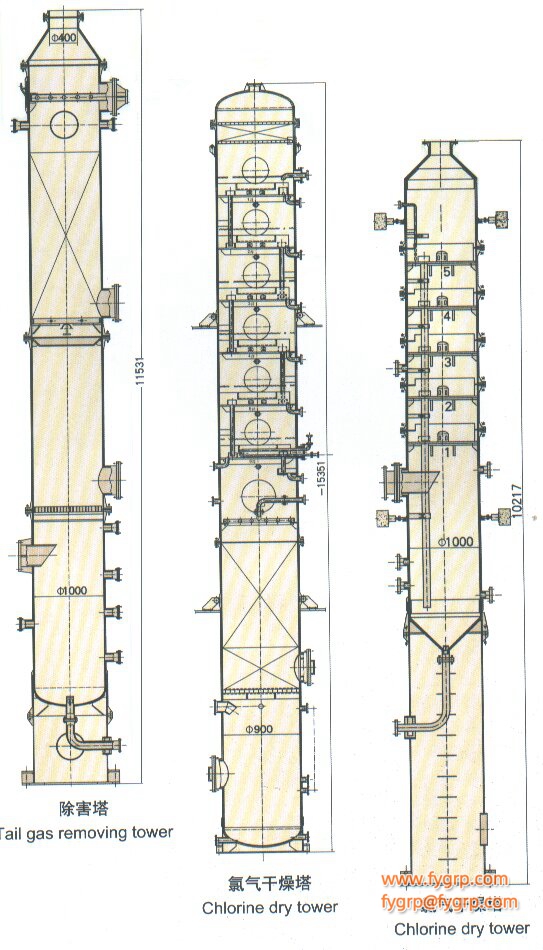

Supplemental system components includes internal and external piping, sprayer, support beams, mist filters, packing, distribution systems and pipe, can be fabricated in any shape or configuration.

The scope of supply of FYGRP covers exterior accessories such as ladders, platforms, handrail, walkway, drainage, electrostatic discharge etc.

FYGRP analyzes each project and reviews the system performance specifications in order to select appropriate materials and construction methods, and finally designs and fabricates FRP scrubbers according to medium, temperature, flow rate, pressure, earthquake, wind load and climate conditions etc.

When necessary, ECR glass fiber can be used in addition to common glass fiber to give higher chemical resistance, and use colored or semi-transparent top coating to resist UV and provide protection.

FYGRP,as a full service supplier, designs, produces and installs equipment for the exterior of scrubber such as ladder, platforms, drainage, protection liner plate and electrostatic discharge, meanwhile, also provides all kinds of internals such as spray banks, support , beams, mist filters and packing.

FYGRP makes the excellent performance of FRP more comprehensive, more reasonable and more effective during the design and manufacturing of tower equipment. At the beginning of design, carries out scientific and reasonable material selection and precise and detailed structural strength calculations according to the usage industry and working conditions (working environment) of the tower equipment, and rely on strict management, advanced equipment, and perfect design in the manufacturing process. Manufacture FRP tower equipment with excellent performance using the process technology. For waste gas treatment, recycling, washing, deodorization and other processes, please provide detailed emission standards and operating conditions.

Please contact tc@fygrp.com for details.

Please contact tc@fygrp.com for details