FYGRP company FRP process pipe production process

FRP process pipe production process

1、Description of pipe wall structure

The pipe wall structure from inside to outside are: inner liner, secondary inner layer, winding layer, and outer protective layer.

The inner liner and secondary inner layer play the role of anti-corrosion and anti-seepage, the winding layer plays the role of strength and stiffness, and the outer protective layer plays the role of anti-aging, anti-corrosion and anti-sunlight.

2、Pipeline production process flow chart

→Mold preparation

→Equipment debugging, raw material preparation

→Making inner liner of pipe

→Inner liner curing at far infrared curing station

→inner liner quality inspection

→Pipe reinforcement layer winding

→Pipe far infrared integral curing

→Pipe appearance and main size inspection

→Pipe demould

→Hydraulic test of 1.5 times working pressure and other standard requirements

→Pipeline packaging and storage

3、Process description

(1)Preparation process

a、Equipment debugging. First, carefully check whether the operation of equipment and working parts are normal, especially whether the resin-curing agent two-component pump is clogged, and whether the ratio meets the design requirement, ensure the stable operation and work accuracy of the equipment such as making inner liner, winding, trimming, demoulding, etc.

b、 Clean mould. The mould surface is required to be free of pits, dust, debris and other attachments. The mould surface should be smooth. If there is a problem, repair and maintain in time.

c、Wrap polyester film. In order to facilitate demolding, a layer of polyester film should be wrapped on the surface of mould. The overlap width of film is 1~2cm and thickness is about 40um. It is required that the film has no damage, no wrinkles, and both sides are smooth and clean. The film quality meets requirements of GB13950-1992.

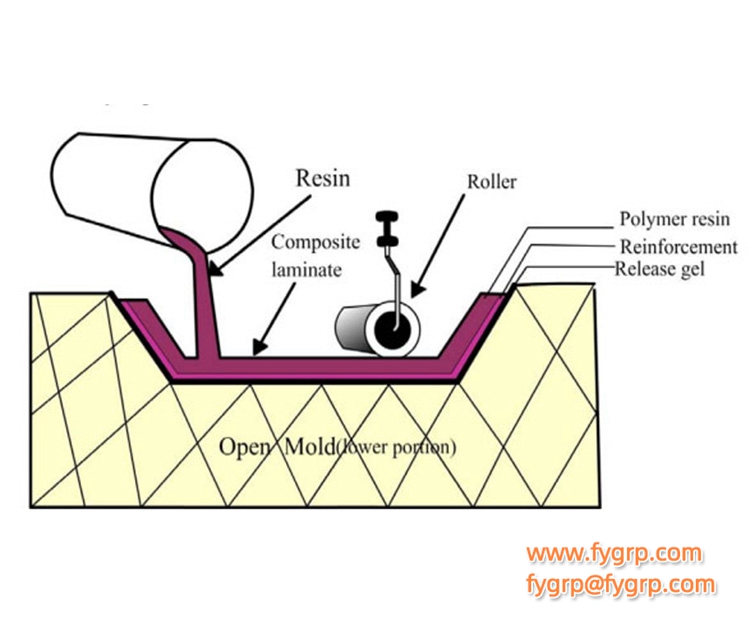

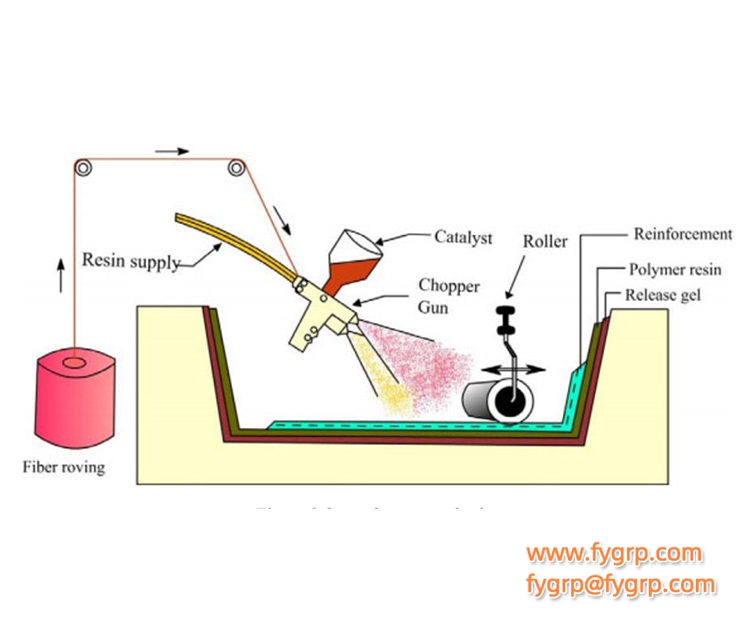

(2)Procedure of making inner liner

a、Inner liner resin preparation. Inner liner resin is mixed by quality inspection department according to resin formula system made base on working environment and temperature at that time, the amount of ingredients should be reasonably controlled according to manufacturing schedule. When the situation changes on-site, the manufacturing department should adjust the formula in time and prepare appropriate resin according to the new formula.

b、Reinforcement material preparation. Reinforcement material of making inner liner is delivered to designated location according to design requirement. Cut the wide-format reinforcement materials to design width.

c、 Making inner liner. Make inner liner according to design lamination sequence. Each single layer should be applied with proper tension during laying process, overlap with each other properly, and drive out bubbles with combined roller repeatedly rolling to ensure the fiberglass is completely permeated with resin. Each reinforced layer is required to reach the design resin content.

d、Preliminary self-inspection. After applying every layer as per design requirement, the operator is required to conduct preliminary quality inspection, whether the inner liner reaches design thickness, whether there is poor glue or hanging in local area, whether there are white spots or bubbles, if so, it should be taken treatment measures immediately.

e、Inner liner far infrared deeply curing process

(3)Far infrared deeply curing

The FRP pipes manufactured by our company must be deep-infrared curing treatment, the purpose is to improve the curing degree of inner liner and enhance corrosion and temperature resistance of the pipe.

(4)Process quality inspection

Reconfirm that the inner liner has no bubbles, pores, impurities, surface is smooth, resin content is reasonable, no white spots and local poor curing before winding. It is necessary to carefully check whether the inner liner is qualified, if not, prohibit to wind on the machine.

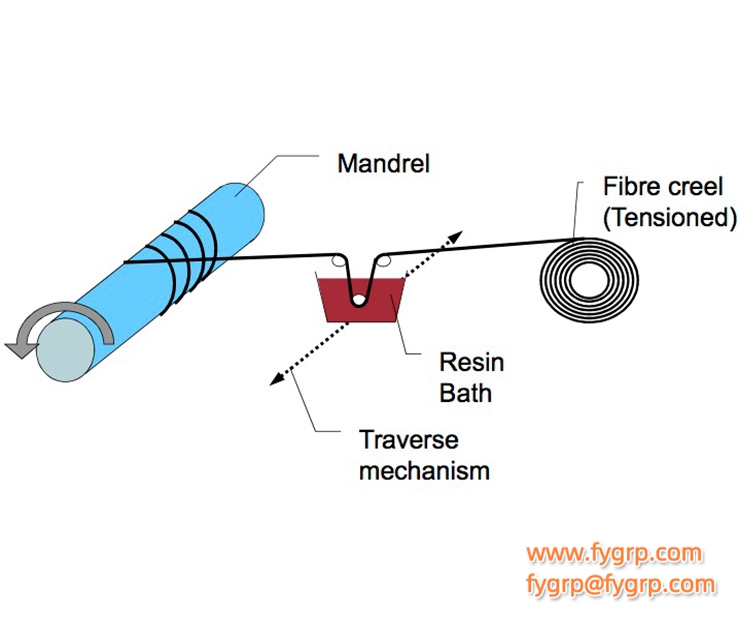

(5)Winding process

Input the designed parameters into the microcomputer, after the inner liner is cured, reciprocally winding with E-glass fiberglass up to thickness of winding layer. External protective layer is applied 100%of resin as per required thickness. The resin content of winding layer is generally about 30%, and its thickness depends on the strength and stiffness of pipeline.

(6)Far Infrared curing

The pipeline enters the curing stage. During the curing process, the mold should be kept rolling at an appropriate speed to make it evenly cured, and attent to monitor temperature of pipe body and reasonably adjust the curing plan.

(7)Trimming and demoulding

Trim the pipe ends when barcol hardness is greater than 30. Then separate the pipe from the mould using hydraulic stripper, and mark on middle of pipe as required.

(8)Pipeline hydraulic test and placement:

Each batch of pipelines is subjected to hydraulic test according to regulations, filled with water, and the pressure is evenly increased to 1.5 times design pressure of pipeline, and keep pressure for not less than 2 minutes. Carefully check pipe surface and pressure gauge. After the pressure test is qualified, the pipeline is placed on support of three points.

Location:Home>Technology